UMC turns to mature 28nm process to combat global semiconductor shortage

Bottom line: A deal of this caliber is unusual for a major contract chipmaker, but desperate times telephone call for desperate measures. The ongoing global chip shortage, caused in part by the Covid-19 pandemic, has forced a rethink across many industries and this is just 1 case of one visitor's way to keep the wheels moving.

United Microsystem electronics Corporation (UMC), 1 of the earth'southward largest contract chipmakers, has announced plans to aggrandize capacity at its 300mm Fab 12A facility in Tainan, Taiwan.

UMC said information technology has worked out an agreement with several of its leading customers that'll guarantee long-term chip supply in commutation for upfront deposits and pre-set up pricing. Phase six, as the program is being chosen, volition be equipped with mature 28nm tools that can after be swapped for 14nm gear to accommodate future roadmaps.

Fab 12A is currently churning out effectually ninety,000 300mm wafers per calendar month (wpm). An additional ten,000 wpm is beingness installed this year and phase six will add together some other 27,500 wpm to the mix.

UMC said it is as well expecting to rent an additional ane,000 employees to assistance support the effort. The total cost of the P6 expansion is earmarked at NT$100 billion, or around $3.6 billion.

TSMC, the world's largest chipmaker, said earlier this month that information technology would be investing over $100 billion across the next three years to heave manufacturing capacity and aggrandize R&D efforts.

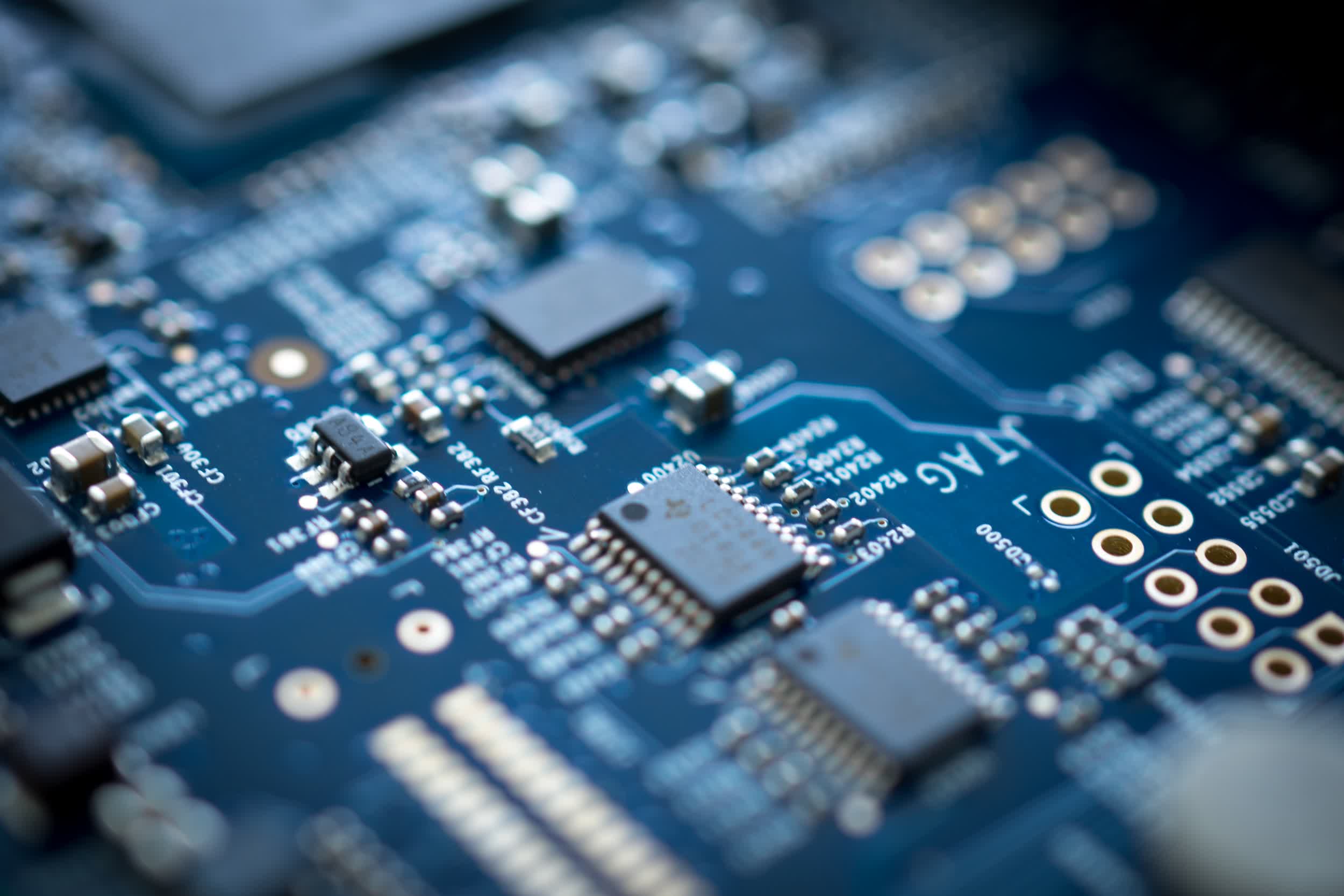

Image credit Macro photograph, Glitterstudio

Source: https://www.techspot.com/news/89497-umc-ramping-up-production-older-28nm-chips-address.html

Posted by: readybunpremong.blogspot.com

0 Response to "UMC turns to mature 28nm process to combat global semiconductor shortage"

Post a Comment